TECHNOLOGY

TECHNOLOGY BORN ON THE RACE TRACK

At PRO LEGGERA, we grew up surrounded by carbon, speed, and the relentless pursuit of every tenth of a second.

Our DNA comes from motorsport – a world where every extra gram can mean the difference between victory and defeat.

PRO LEGGERA shin guards were born from our long-standing experience in manufacturing and repairing epoxy composites for motorsport and high-performance sports cars.

We use advanced composite materials such as FORGED Carbon, carbon fiber, and Kevlar – the same materials that protect drivers' lives even at speeds exceeding 300 km/h.

Legendary engineer and Lotus founder Colin Chapman once said:

"Add power and you'll be fast on the straights. Subtract weight and you'll be fast everywhere."

We've taken that philosophy to heart.

Our latest project and testing platform is a Lotus Elise Supercharged, which we have transformed into a track CUP version with a complete FORGED Carbon body kit, designed and produced at PRO LEGGERA.

OUR SHIN GUARD MANUFACTURING TECHNOLOGY

FORGED Carbon – strength in every detail

FORGED Carbon is a modern composite material created by pressing short carbon fibers under high pressure and temperature. This process produces a unique structure with exceptional strength and low weight. Every pair of shin guards has an original look, as no two pieces of FORGED Carbon are ever the same.

Carbon – maximum rigidity, minimum weight

Traditional carbon fiber composite provides the shin guards with extreme impact resistance and perfect stiffness while maintaining minimal weight. This ensures the guards fit perfectly to the leg without restricting movement.

Kevlar – protection inspired by military technology

Kevlar is an aramid fiber known from the production of bulletproof vests. In our shin guards, it reinforces the most stressed areas and ensures high resistance to penetration and wear. Combined with carbon, it creates the ideal balance between flexibility and strength.

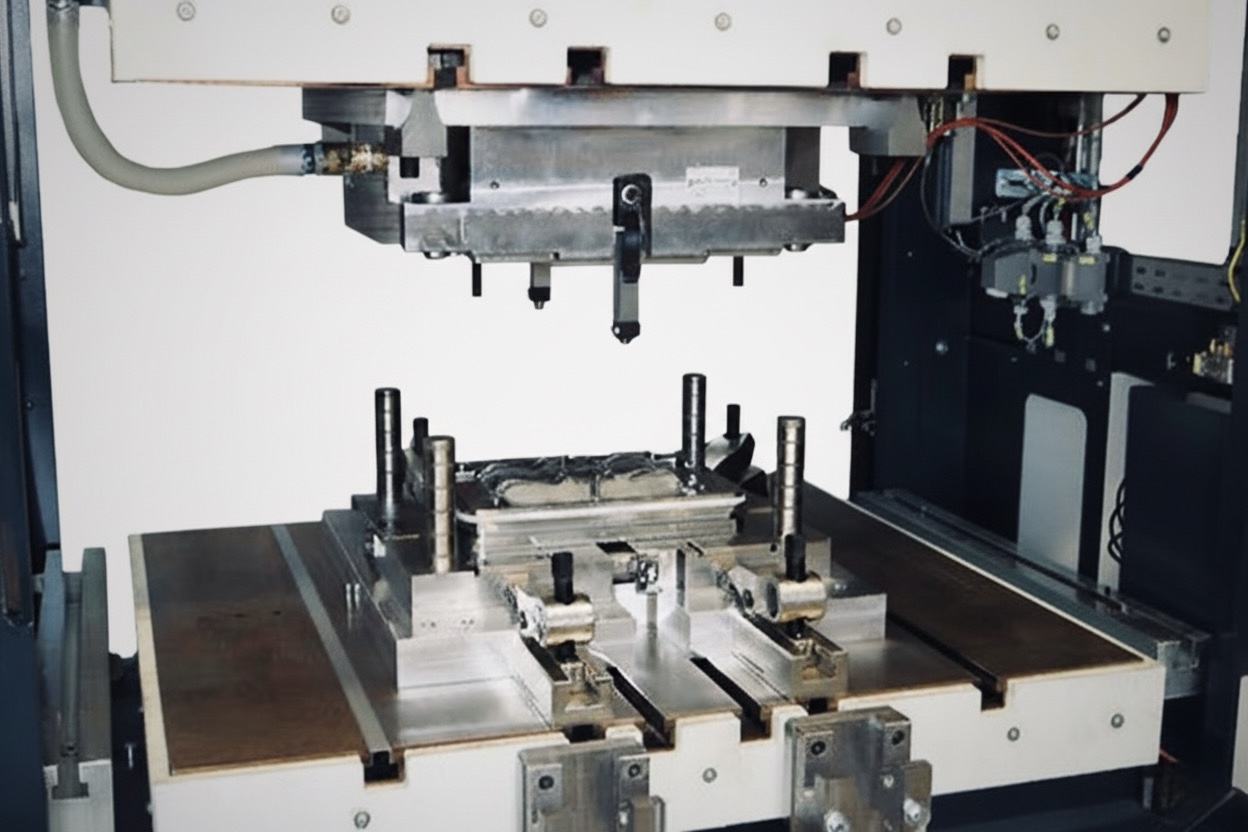

Precise handcrafting

Each shin guard undergoes a meticulous process of hand layering and pressing. This ensures top-tier quality, perfect shape, and long-lasting durability. Every detail is carefully checked to meet professional standards – from the choice of resins to the final surface finish.

AUDIOPHILE PRECISION & COMPOSITE MASTERY

Our expertise extends beyond the race track.

For over a decade, we've been manufacturing carbon tonearms for turntables, among the finest in their class worldwide.

In the audio industry, just like in motorsport, every micron, every resonance, and every tiny detail matters.

Where others seek compromises, we seek the perfect balance between stiffness, lightness, and purity of transmission.

WE PRESERVE PERFECTION – EVEN WHEN DAMAGED

We understand composites down to the last fiber – not only in their manufacture but also in their repair.

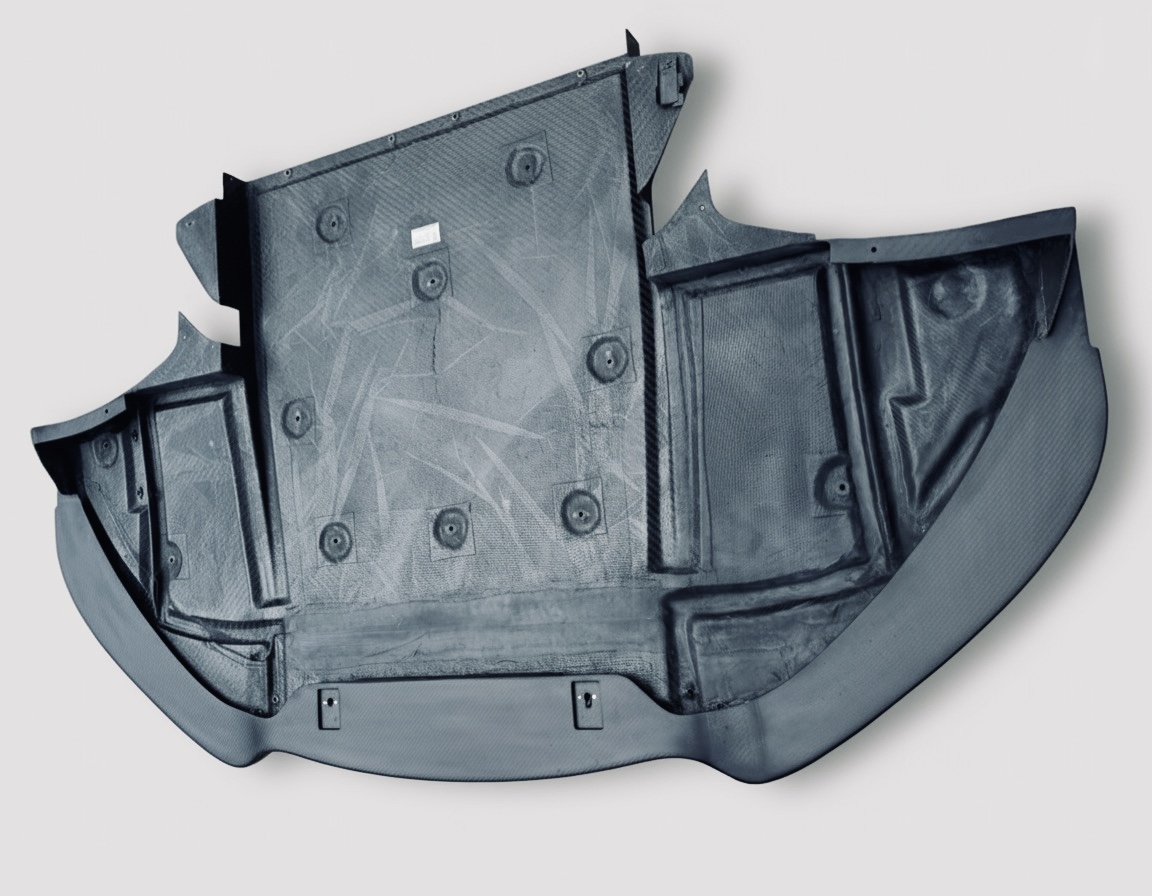

We specialize in the restoration of damaged carbon components from motorsport, bicycle frames, and other carbon structures.

Where others see the end of a component's life, we see a challenge to restore it to perfection.

Thanks to this experience, we understand the material deeply – its limits, reactions, and behavior under extreme stress.

And it's precisely this knowledge that allows us to create products combining minimal weight, maximum strength, and flawless functionality.